slotted filter water v shaped wedge wire screen flat screen panel

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge wire screen |

| Application: | solid,liquid and solid,gas separation, sizing, dewatering and media retention in Oil & Gas wells |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

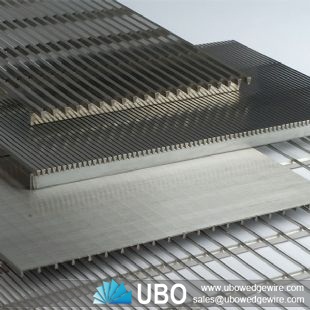

Details of slotted filter water v shaped wedge wire screen flat screen panel

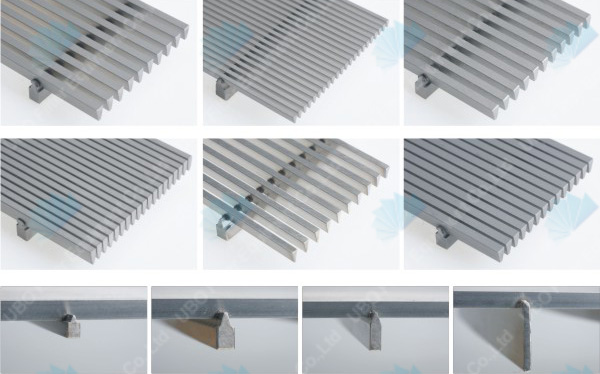

Welded wedge wire screen panels can be constructed using rectangular support rods or round support rods. They are the most widely used type of wedge wire screens mainly in the mineral processing both for stationery as well as vibratory decks.

Advantages for slotted filter water v shaped wedge wire screen flat screen panel:

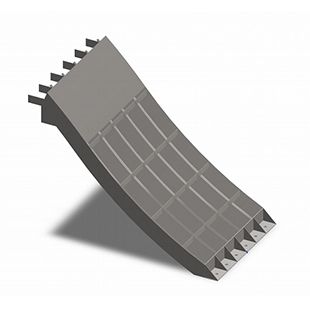

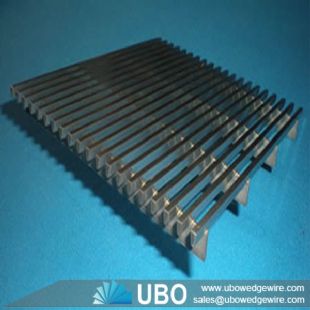

A continuous slot opening which significantly increases the available open area, thus providing a greater access to the water bearing zone.

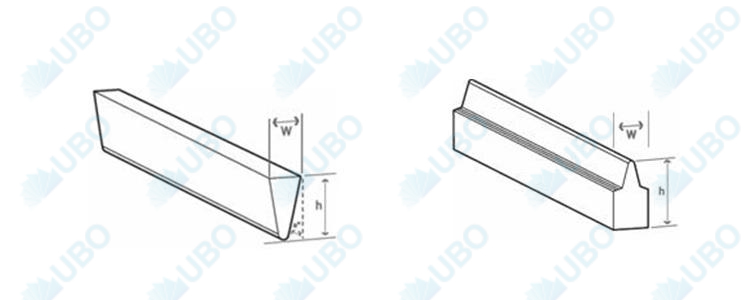

A 'V' shaped wedge wire which avoids clogging and ensures uninterrupted flow.

A uniform and efficient well development due to the continuous slot opening.

Offering great strength. precision, long service life.

Applications for slotted filter water v shaped wedge wire screen flat screen panel:

Wedge wire products are used for solid,liquid and solid,gas separation, sizing, dewatering and media retention in Oil & Gas wells, Water Wells, monitoring & soil sanitation, the (petro) chemical industry, food and process industry and architecture

Characteristic for slotted filter water v shaped wedge wire screen flat screen panel:

Flat screen panel can be designed to optimize the open area, strength and wear life for each application. The panels are either continuously or intermittently welded on the lower side of loop to provide complete rigidity to the panels thus becoming very effective in transmitting the vibrations without mechanical failures.

Specifications of slotted filter water v shaped wedge wire screen flat screen panel:

|

Basepipe OD (in)

|

Perforations per foot

|

Basepipe Hole Size (in)

|

Open Area of Basepipe Holes (in2/ft)

|

Wrap Wire Size Keystone (in)

|

Rib Wire Size Round (in)

|

Maximum OD (in)

|

|

1.05

|

54

|

0.312

|

4.14

|

0.09*0.09

|

0.125

|

1.489

|

|

1.315

|

66

|

0.312

|

5.06

|

0.09*0.09

|

0.125

|

1.726

|

|

1.66

|

78

|

0.312

|

5.98

|

0.09*0.09

|

0.125

|

2.126

|

|

1.90

|

42

|

0.375

|

4.63

|

0.09*0.09

|

0.125

|

2.387

|

|

2.063

|

42

|

0.375

|

4.63

|

0.09*0.09

|

0.125

|

2.55

|

|

2.375

|

54

|

0.375

|

5.96

|

0.09*0.09

|

0.125

|

2.86

|

|

2.875

|

66

|

0.375

|

7.28

|

0.09*0.09

|

0.125

|

3.362

|

|

3.25

|

78

|

0.375

|

8.61

|

0.09*0.09

|

0.125

|

3.737

|

|

3.50

|

78

|

0.375

|

8.61

|

0.09*0.09

|

0.125

|

3.987

|

|

4.00

|

90

|

0.375

|

9.94

|

0.09*0.09

|

0.125

|

4.487

|

|

4.50

|

102

|

0.375

|

11.26

|

0.09*0.09

|

0.125

|

5.001

|

|

5.00

|

114

|

0.375

|

12.59

|

0.09*0.09

|

0.125

|

5.506

|

Packaging and Transportation of slotted filter water v shaped wedge wire screen flat screen panel: