application of wedge wire strainer in water treatment

Wedge wire strainers also referred to as slotted wedge wire screens, are widely used in water treatment to remove impurities and sediment from raw water sources. They are efficient, cost-effective, and easy to maintain. They come in various shapes and sizes and can be used in a variety of applications and industries.

The self-cleaning wedge wire strainer comprises v-shaped wire profiles and support profiles. Its purpose is to capture impurities and sediment as water passes through, enabling the flow of clean water.

There are some typical applications of wedge wire strainers and filters in water treatment.

▪Municipal Water Supply:

Wedge wire strainers play an integral role in municipal water supply systems worldwide. These strainers are used at various stages such as pre-treatment before membrane filtration or reverse osmosis processes. They efficiently remove suspended solids like sand, silt, algae, debris, and other particulate matter from raw water sources such as rivers or lakes.

Wedge wire filters used in municipal water supply applications include wedge wire screen flat plates, stainless steel filter nozzles, curved wedge wire screens, intake screens, and more.

▪Industrial Filtration Systems:

Industries often require large quantities of clean water for manufacturing processes; however, untreated or poorly filtered industrial wastewater can be harmful to both the environment and equipment longevity. By incorporating wedge wire strainers into their filtration systems, industries can achieve high-quality treated process waters while safeguarding machinery from damage caused by solids accumulation.

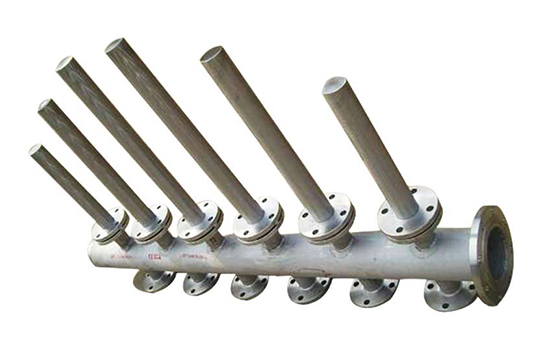

V wire screen filters for industrial filtration systems include wedge wire cylinders, pipes, wedge wire profile screen laterals, and more.

▪Desalination Plants:

The stainless steel wedge wire filter screen strainer act as a preliminary barrier for larger particles present in seawater before it enters the desalination process. This reduces fouling and extends membrane life, making the overall desalination process more efficient.

▪Cooling Tower Systems:

By installing wedge wire strainers at the cooling tower's water inlet, solid particles are effectively removed from entering the system. This prevents clogging of pipes and heat exchangers while ensuring uninterrupted cooling performance.

▪Aquaculture Industry

One vital application of wedge wire strainers is intake screening. They are installed at the entrance points where water is drawn into aquaculture facilities from external sources such as rivers or oceans. These screens act as a first line of defense by preventing larger debris like seaweed, leaves, or other floating matter from entering the system.

Furthermore, when it comes to fish hatcheries, these wedge wire filter DSM screens are highly effective in removing fine particulate matter that poses a potential risk to the delicate development of fish embryos and larvae.

Conclusion

Wedge wire strainers are highly effective in removing impurities and sediment from water sources. We can provide and custom design various types and sizes of stainless steel v wire screens for water treatment. Please contact us at any time to get a quote. Our email address is sales@ubowedgewire.com