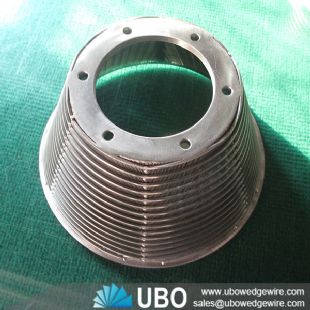

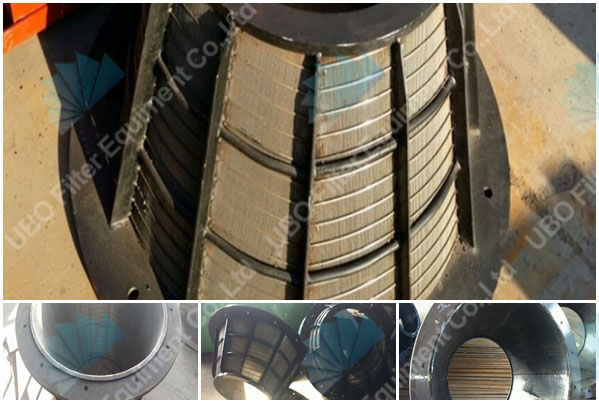

High quality stainless steel vertical vibrating centrifuge sieves

| Category: | Wedge Wire Screen Basket |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | sieve basket screen |

| Application: | mining, coal, petroleum, chemical fertilizer, food, environmental protection and other industry to sew sieve net, oil filter, salt indu |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Detailed description of the High quality stainless steel vertical vibrating centrifuge sieves

stainless steel centrifuge sieves and profile screens are all custom made. Length, width, shape and spacing of profile wire are engineered to meet your special job requirements. And the individual wire on the working surface of the wedge wire screen or stainless steel screen can be manufactured at various angles to better serve your needs.

Application for High quality stainless steel vertical vibrating centrifuge sieves:

Centrifuge screen is specially used in separation of fiber and starch. The body has a fully high quality stainless structure, with the character of anti- erosion, anti- oil, and anti-dirty through a special surface treatment. Sieve basket is the key assembly and it must be strictly checked with centrifugal balance test by authoritative department to make sure its stable running. The centrifugal sieve with high capacity, reasonable power efficiency, and high starch extraction ratio.

Features for High quality stainless steel vertical vibrating centrifuge sieves:

1. Combining the latest technology and years experience into a a whole.

2. Key components introduced abroad, lone service life, low maintenance cost.

3.All parts contact with material are stainless steel, no material contamination.

4.Sieve basket is calibrated through dynamic equilibrium by domestic authority body.

5.Sieve made from laser perforating on titanium alloy plate.

6.To facilitate the automatic design for centrifugal sieve group, CIP system and chain automatic control can be easily realized.

7.Advanced surface treatment technology ensuring the good looking and resistance of oil and dirt.

8.Nozzles tested by strict examination in pressure and flow rate

9.Big capacity, low power consumption, stable operation, high starch extraction rate and easy installation.

10.Widely used for starch extraction in starch processing factory.

Work Principle for High quality stainless steel vertical vibrating centrifuge sieves:

The equipment screen mesh is a cylinder, material, after handling by screw feeder, mixing and atomization into a screen cage, so that the material also driven by centrifugal force and cyclone by rotating the blade, forcing material injection over the screen cage, fine material discharge from fine outlet, the coarse material which can not cross the screen cage, discharged from the coarse outlet.

The specifications of the High quality stainless steel vertical vibrating centrifuge sieves:

Triangle wire size:

| Triangle wire | Width | 1.5mm | 2.2mm | 2.8mm | 3.1mm | 3.4mm | 5.0mm |

| height | 4.0mm | 4.5mm | 5.0mm | 6.0mm | 7.5mm | 10.0mm | |

| Slot | 0.10mm-10mm | ||||||

Support rod size:

| Support rod | Width | 1.0mm | 1.5mm | 1.8mm | 2.7mm | 3.2mm | 3.6mm |

| height | 2.0mm | 2.5mm | 3.0mm | 4.2mm | 5.3mm | 5.7mm | |

| Slot | 0.2mm-5mm | ||||||

The Packaging and Transportation of the High quality stainless steel vertical vibrating centrifuge sieves: