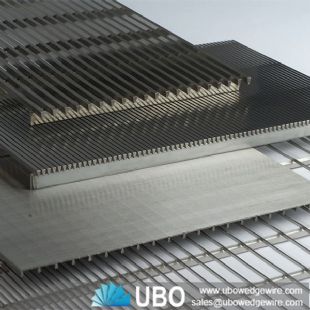

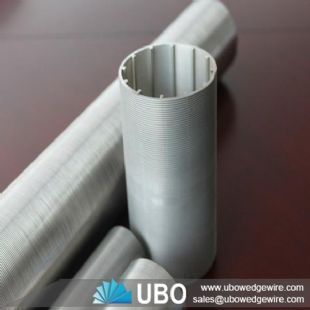

V-shaped steel wire welded stainless steel screens

| Category: | Wedge Wire Application |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | wedge wire screen |

| Application: | water treatment, water softhening, conversion of sea water into fresh water, the filter of food chemistry |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of V-shaped steel wire welded stainless steel screens

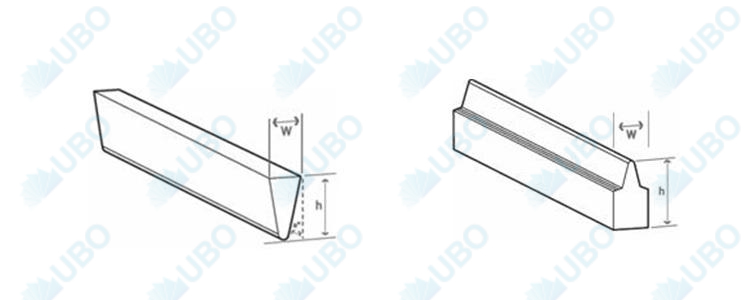

Stainless steel wedge wire screens are made of SS V shaped and SS V shaped or SS V shaped and SS rod or SS V shaped and SS Convex shaped rod with the unique computer controlled machinery in which a continuous length of profile wire of a triangular section is fusion welded into support rods. This V shaped profile wire is wound around the support rods over the full length of the screen thus creating a continuous slot opening.

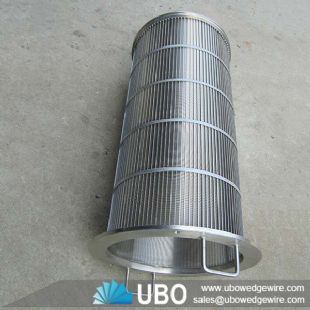

Applications for V Shaped Wire Welded Screens:

The strainer is a kind of filtered water tubing with the perforation. it can be used with the deep well pump, dive the water pump, also has may use in the water-treating equipment, the environmental protection, the sea water transforms into the industrial water and life use water desalination treatment, running water treatment, water softening treatment, the petroleum industry: The petroleum product terminal filters and the chemical acid, the alkali liquid filters, the ethyl alcohol and so on the organic solution recycling filter

Features for V Shaped Wire Welded Screens:

1) Screens with high open area are more suitable for the construction of high-quality water wells and gas wells.

2) Low cost operation

Screens with high open area shall favor groundwater infiltration.Abundant water shall reduce the water level’s down,thus to save energy consumption.

3) Reduce the abrasion of the pump

Under the same condition,high open area can make the speed of groundwater’s entering into the screen much more slower than any other filtration apparatus,which will avoid sand’s entering into screen because of high pressure,thus reduce the abrasion of the pump.

4) Extend the life span of wells

Comparatively,groundwater’s entering into screen with higher open area is much easier than the entering into lower open area screen.The slow water flow shall extend the life span of wells.

Advantage for V Shaped Wire Welded Screens:

1) A continuous slot opening which significantly increases the available open area,thus providing greater access to the water bearing zone.

2) A “V”shaped profile wire which avoids and ensures an uninterrupted flow.

3) A uniform and efficient well development due to the continuous slot opening.

4) Ladder-like wire water well screens have a structure and high open area,as well as accurate slot dimension.

5) Ladder-like wire water well screens have the features of easy backwashing,long life span,safety and reliability as low comprehensive cost.

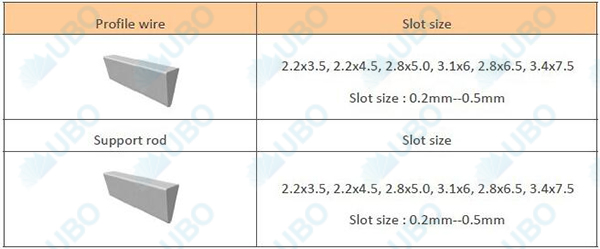

Specifications of V-shaped steel wire welded stainless steel screens:

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Diameter |

from 25mm to 1200mm. |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

Packaging and Transportation of V-shaped steel wire welded stainless steel screens: