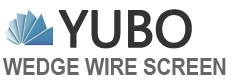

stainless steel wedge wire welded drum screen

| Category: | Wedge Wire Pipe&Cylinder |

|---|---|

| Material: | SS 304,316,316L, Stainless steel and carbon steel. |

| Properties: | Wedge wire screen |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Detailed description of the stainless steel wedge wire welded drum screen

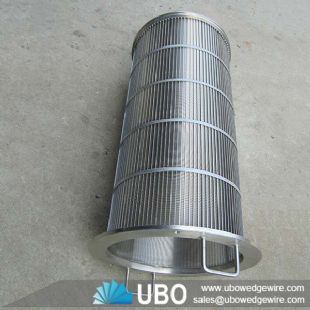

Wedge Wire Drum Screen consist of V-shape profile wire and the longitudinal support rods.The V wire is welded to the rods and produces a rigid unit that has high strength and minimum weight.So Water Well Screens has sturdy constriction and good mechanical property.

Application for stainless steel wedge wire welded drum screen:

Rotary Drum Screens are used to mechanically separate liquids from solid particles. Gap Technology offer a wide range of Rotary Drum screens and Rotary Wedge Wire Screens / Trommel Screens for industrial waste water screening applications to our large and varied customer base throughout the United Kingdom and across Europe.

Characteristics for stainless steel wedge wire welded drum screen:

High mechanical strength

High wear resistance

High impact resistance

Larger open area

Self-supporting structure

Non-plugging slot design

Lower operation and maintenance cost

Advantages for stainless steel wedge wire welded drum screen:

1.Production process continuity: V-shaped profile wires creating slots which enlarge inwardly and therefore avoid clogging and minimize downtime.

2.Low maintenance costs: Separation at the screen surface which can easily cleaned by scraping or back washing.

3.Maximum process output: Precise and continuous slot openings resulting in accurate separation without loss off media.

4.Low operational costs: Large open area with an effective flow, high yield and a low pressure drop (dP)

5.Long live: Welded at each intersection creating a strong and durable screen.

6.Reduced installation costs: supporting constructions eliminating costly support media and enabling a maximum flexibility in the design of components.

7.Chemical and thermal resistant: A variety of corrosion resistant stainless steel materials and many exotic alloys suitable for high temperatures and pressures.

The specifications of the stainless steel wedge wire welded drum screen:

|

Specification (wedge wire):

|

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00

|

|

Specification (support rod):

|

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30

Round: From 2.50mm to 6.0mm

|

|

Note: other specifications available as per request

|

|

|

Slot size

|

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request.

|

|

Material:

|

galvanized low carton (LCG), stainless steel (304,316 etc.)

|

|

Length

|

up to 6 meters.

|

|

Diameter

|

from 25mm to 1200mm.

|

|

End connection

|

Plain beveled ends, flanged or threaded couplings

|

The Packaging and Transportation of the stainless steel wedge wire welded drum screen:

Single with bubble bag and then in wooden case(fumigation certificate). Each case is clearly

marked with:

Name & identification mark of manufacturer-HuaDong Brand

Batch number

Date of manufacture

Material

Safe heating & application temperature