Johnson Wedge Wrapped Wire Screen Cylinder

| Category: | Wedge Wire Pipe&Cylinder |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | filter Cylinder |

| Application: | water treatment, oilfield, mining, food industry, chemical industry, papermaking industry, decoration. |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

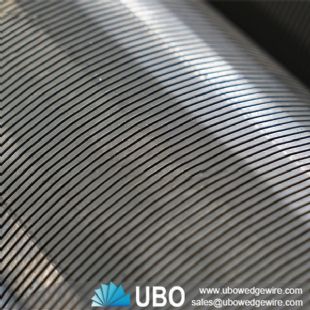

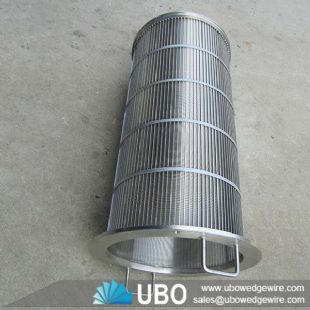

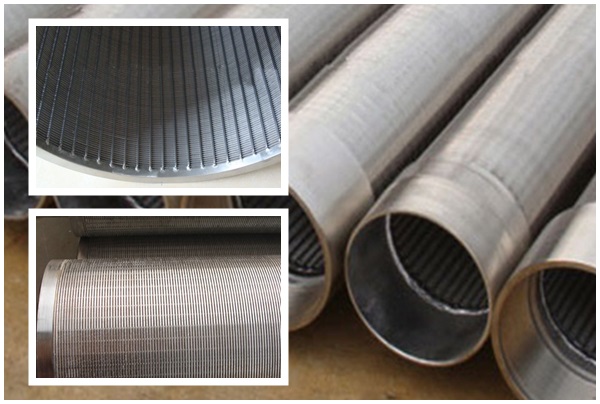

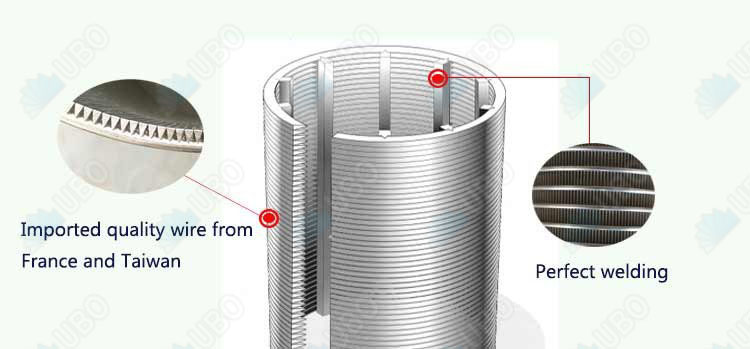

Details of Johnson Wedge Wrapped Wire Screen Cylinder

UBO offers a reliable and efficient range of Stainless Steel Wedge Wire Filter Cartridges. Our offered products are extensively demanded by various industries and are manufactured in accordance with the industry set norms and guidelines. Post-production, we test each product on various stages to give our clients

Features for Johnson Wedge Wrapped Wire Screen Cylinder:

1) Custom Designed and Engineered

Each project is specifically designed to ensure complete satisfaction. We provide guidance and support from project concept to completion.

2) Longer lasting.

Wedge Wire Screens, whose manufacturing standards are the most stringent in the industry, are extremely durable and have high resistance to abrasion, corrosion and impact damage.

3) Lower Maintenance.

The rugged construction and high quality of materials make possible a product that lasts longer and requires less maintenance.

4) Less Costly.

Superior operating efficiency, extended service life and reduced main-tenance needs combine to reduce the true cost of Wedge Wire screens to plant operators.

Application for Johnson Wedge Wrapped Wire Screen Cylinder:

Different kinds and specifications of screens are used in motor-pumped wells and geothermal wells.

Architects specify Wedge Wire screens for column and wall covers, grating floor, light fixtures, sun screens and various decorative applications.

Wedge Wire screens are used on food processors because they are heat and corrosion resistant and make it easier for FDA approval.

Malting plant operators find our flat panel screens provide a more thorough mixing during the turning phase, and better ventilation in the kilning phase.

Pulp and paper plants use our screens in the wood yard, paper machines, recycling, dewatering, debris removal, fiber fractionalization, drying, water purification and other processes.

Wedge Wire Screens are also applied in mineral processors, refiners, waste water treatment and water supply systems.

Technology for High Quality Johnson Wedge Wrapped Wire Screen Cylinder:

Manfre introduce advanced korea technology , the construction method used is the latest, ultra clean TiG and plasma welding system. This method of construction guarantees cartridge integrity, eliminating the risk of bypass and the presence of extractables derived from any bonding agents.

Specifications of Johnson Wedge Wrapped Wire Screen Cylinder:

|

Screen Size

|

ID

|

OD

|

Female thread dismeter

|

||||

|

in

|

mm

|

in

|

mm

|

in

|

mm

|

in

|

mm

|

|

2

|

51

|

2

|

51

|

25/8

|

67

|

23/4

|

70

|

|

3

|

76

|

3

|

76

|

35/8

|

92

|

33/4

|

95

|

|

4

|

102

|

4

|

102

|

45/8

|

117

|

43/4

|

121

|

|

5

|

127

|

5

|

127

|

55/8

|

143

|

53/4

|

146

|

|

6

|

152

|

6

|

152

|

65/8

|

168

|

7

|

178

|

|

8

|

203

|

8

|

203

|

85/8

|

219

|

91/4

|

235

|

|

10

|

254

|

10

|

254

|

103/4

|

273

|

113/8

|

289

|

|

12

|

305

|

12

|

305

|

123/4

|

324

|

133/8

|

340

|

|

14

|

356

|

13 1/8

|

333

|

14

|

356

|

-

|

-

|

|

16

|

406

|

15

|

381

|

16

|

406

|

-

|

-

|

|

20

|

508

|

18 3/5

|

476

|

20

|

508

|

-

|

-

|

Packaging and Transportation of Johnson Wedge Wrapped Wire Screen Cylinder:

1) Each product is packed with bubble bag and then few bags to a wooden case (fumigation certificate)

2) We have a very trust forwarding company cooperate for long time and establish a solid partnership,of course,you can also arrange forward to take products from our factory.