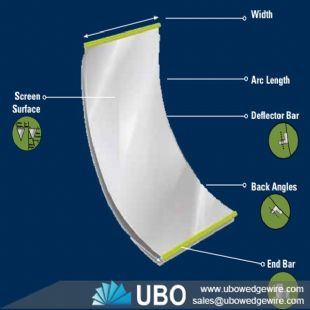

wedge wire screen for food & beverage processing

| Category: | Sieve Bend Screen |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | wedge wire screen |

| Application: | water-treatment, mineral processing, coal-cleaning plant |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of wedge wire screen for food & beverage processing

Wedge wire screens for food&beverage processing are known as side hill screens, parabolic screens, run down screens, gravity screens and DSM screens.

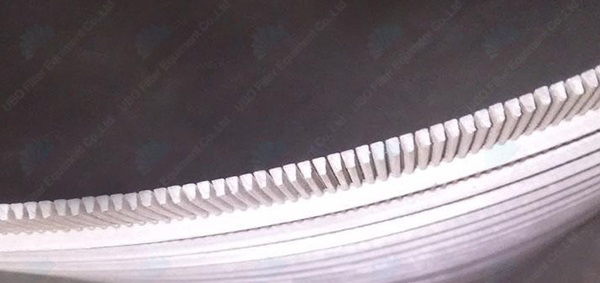

Wedge wire screen has greater capacity than a flat wedge screen due to forces exerted as material flows against the curved surface. YUBO wedge wire curved screens are wear-resistant and easy to use, and plays an important role in food and beverage filtration.

Advantages of Wedge Wire sieve bend screen for Food & Beverage Processing

Wedge Wire Screens offer several advantages for food and beverage processing applications, making them a preferred choice in the industry. Some of the key advantages include:

Hygienic Design: Wedge Wire Screens are designed with hygiene in mind. They have smooth surfaces without any crevices or pockets that can trap bacteria or contaminants. This design feature ensures compliance with strict sanitary standards required in food and beverage processing.

Efficient Solid-Liquid Separation: These screens excel at solid-liquid separation processes, effectively removing solid particles such as pulp, skins, seeds, and other debris from liquids during various stages of food and beverage production.They provide high filtration efficiency while allowing liquids to pass through easily.

Durable Construction: Wedge Wire Screens are manufactured using high-quality materials like stainless steel that offer excellent durability even when exposed to harsh environments or repeated cleaning cycles.These screens can withstand rigorous use without compromising their structural integrity,making them suitable for continuous operation within demanding food and beverage processing facilities.

Specifications of wedge wire screen for food & beverage processing:

|

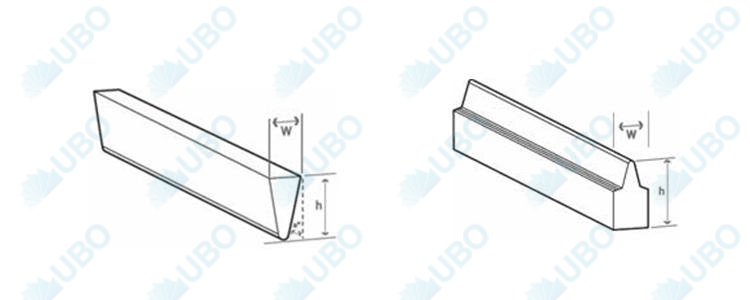

Specification (wedge wire):

|

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00

|

|

Specification (support rod):

|

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30

|

|

Note: other specifications available as per request

|

|

|

Slot size

|

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request.

|

|

Material:

|

galvanized low carton (LCG), stainless steel (304,316 etc.)

|

|

Length

|

up to 6 meters.

|

|

Width

|

from 25mm to 1200mm.

|

|

End connection

|

Plain beveled ends, flanged or threaded couplings

|

Packaging and Transportation of wedge wire screen for food & beverage processing: