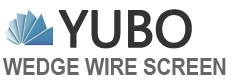

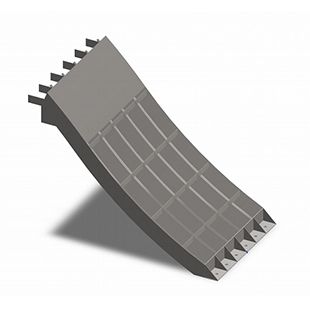

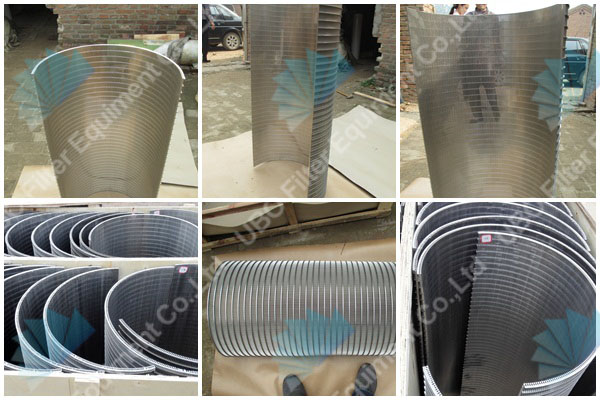

wedge wire screen for dewatering equipment

| Category: | Sieve Bend Screen |

|---|---|

| Material: | stainless steel 304,304L,304HC,316,316L,321,430 or as per your request. |

| Properties: | Sieve Bend Screen |

| Application: | mining, coal, petroleum, chemical fertilizer, food, environmental protection and other industry to sew sieve net, oil filter, salt indu |

if you are interested in receiving more information or have a question regarding any of our products please fill out the form above and we will contact you within 24-48 hours.

Details of wedge wire screen for dewatering equipment

Wedge wire curve screen is a screen surface for the arc to open away from wet fine screening equipment. According to the different feeding methods are divided into gravity and pressure arc curved sieve screen. Artesian curved screen is a small curvature, low pressure, low-speed feeding curved screen, thanks to a certain height difference of the feed material screening and to the mouth, along the arc tangent in the direction screen surface for gravity feed. Pressure is a sweeping curved screen, high-pressure, high-speed feeding curved screen, which is the use of sand pump nozzle into the raw material to the slurry under the action of the material at high speed along the curved screen surface tangent to the direction of the pressure feedstock.

Used for wedge wire screen for dewatering equipment:

The uses are sewage treatment, laundry wash water clean-up, poultry, fish, fruit and vegetable wastewater processing, minerals processing, coal preparation, paper production, textile plants, and many more.

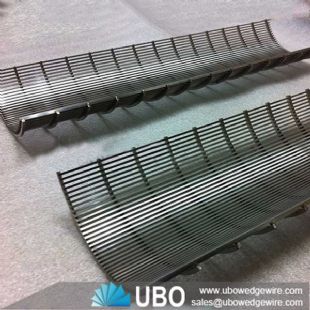

Advantages for wedge wire screen for dewatering equipment:

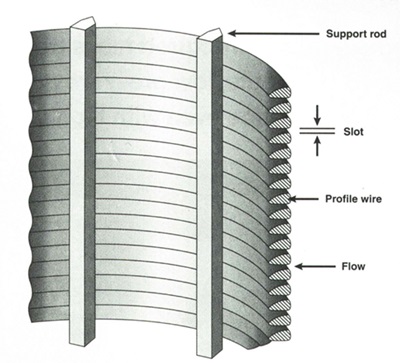

1 A continuous slot opening which significantly increases the available open area, thus providing greater access to the water bearing zone.

2 A "V"shaped profile wire which avoids clogging and ensures an uninterrupted flow.

3 A uniform and efficient well development due to the continuous slot opening.

4 Ladder-like wire welded screens have a strong structure and high open area, as well as accurate slot dimension.

5 Ladder-like wire welded screens have the features of easy backwashing, last long, safety and reliability as well as low comprehensive cost.

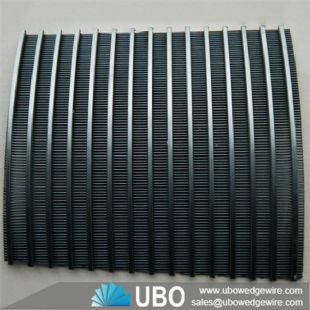

Constructions for wedge wire screen for dewatering equipment:

A combination of different support profiles and pitches within one flat screen is possible

Variable spacing between support wires in one screen

Curved screens; curve direction and filtration direction are to be determined by the customer.Frames and reinforcements can be designed and calculated on request, provided that we know the temperature, supports and differential pressure

Specifications of wedge wire screen for dewatering equipment:

|

Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70

Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

|

Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70

Height(mm): 2.70 3.60 4.70 5.60 6.30

Round: From 2.50mm to 6.0mm |

|

Note: other specifications available as per request |

|

|

Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

|

Material: |

galvanized low carton (LCG), stainless steel (304,316 etc.) |

|

Length |

up to 6 meters. |

|

Width |

from 25mm to 1200mm. |

|

Radian |

120º |

|

End connection |

Plain beveled ends, flanged or threaded couplings |

Packaging and Transportation of wedge wire screen for dewatering equipment: